|

|

|

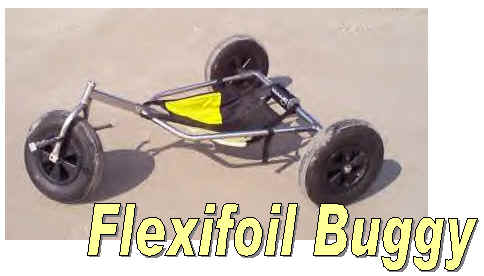

Flexifoil Original Buggy

|

Specifications |

|

|

Name: |

Flexifoil |

The Flexifoil was designed by Mr Peter Lynn himself. It is made entirely from stainless steel (the buggy). Like most tubular buggies it consists of 4 section.

1. A 32mm rear axle. This axle is made up of 3 tubes welded together to raise the seat height.

2. A chassis made from curved tubes, attached to the axle and a box-shape seat. This seat is made from highly reinforced canvas and woven fabric (netting) to allow any water which may get in to drain away.

3. The front segment is a square section and can be adjusted in length.

4. The fork, front wheel and the 2 pegs which are fixed to the fork by 2 screws. Ground clearance: 15 cm

SUITABILITY FOR FREESTYLE

You can perform every possible and imaginable figure. The manufacturer's video

shows this clearly.

GROUND HUGGING CAPABILITY

Very good, thanks to the particularly low centre of gravity. Nevertheless, the

Flexifoil experiences the same skidding problems as the Peter Lynn.

COMFORT

The seat on this buggy is rather special, and not everyone would like it. It is

also quite narrow, so only smaller drivers will find it comfortable. Once the

driver is wedged well into the seat, the Flexi Buggy is, in fact, quite

comfortable. We recommend adding a back rest. With it's low ground clearance,

your backside is in for a pounding. Furthermore, there is no protection in

front.

KP'S VERDICT

The Flexifoil is a very fine buggy offering good value for money. It's

suitability for freestyle and long distance/leisure makes it one of the most

versatile around. The buggy's structure is quite flexible, but it handles

repeated bumps well. The box used for the seat is likely to wear quickly because

of repeated rubbing by the harness. A full range of spare parts can be orderred.

Pity that Flexi's welds are a bit clumsy.

|

For |

Against |

|

Can be dismantled fully |

For small people only |

Flexifoil Sport Buggy

|

Specifications |

|

|

Name: |

Flexifoil |

This buggy has been out for over a year now, but I had yet to see one in person.

All I had seen until this past weekend was the catalog photo of it on the Cobra

Kites web page. The photo left much to be seen; what did that rear axle look

like up close? How was it configured? How important was that back seat strap to

the integrity of the buggy?

Even without seeing or sitting in one, I went ahead and placed an order with my

local retailer (Kites Etc. of Newport and Sunset Beach, Ca). I figured the price

was good (quite a bit lower than the regular flexi buggy), and that Peter

couldn't make a bad buggy. He hasn't.

The buggy is very light weight, or at least it's lighter than my current old

flexi buggy (the model with all the welds and bends in the back axle). The

wheels are set back a tad further than the original, and the distance from

center of tire to tire across the buggy is about 101cm. Mine came with the

wheels displaying no toeing outward or inward (the main reason I got a new buggy

as the wheels on my old buggy are toed and tilted, maybe from to much 2

wheeling). The frame consists of the front forks and down tube (bearing headset,

which I don't care for), 2 side tubes, and a back tube. The back tube, along

with the seat, holds the side tubes together in the back. Unlike all other

buggies I've seen, the rear wheel mounts are on the side tubes. The side tubes

have quite a few bends and 3 welds along the length.

The back tube is quite small and is simply a long U. It fits into short tubes

on the side tubes with no buttons. All the welds are very clean, and the whole

thing is polished.

Assembly is easy except for where the side tubes connect to the down tube. One

of my side tubes is *extremely* tight on the down tube, to the point where one

needs to insert the bolt and tighten the joint to get the down tube fully

in-between the 'rails' of the side tube. Quite a pain the bum. Only 2 straps of

the seat have to go on part of the frame (the back tube) before the frame is

assembled. The rest is done with plastic connectors. The seat has two

adjustments. One of these is wrapped around the side tubes once.

At first I mistakenly wrapped it twice; it made for a narrower seat. The

other adjustment raises and lowers the seat. I feel it needs a longer strap; I

think I'd rather have my bum a little lower in the buggy.

For all you folks who didn't like the original flexi buggy because of the seat

(which they have redesigned according to their catalog), this one shouldn't give

you much trouble. I wouldn't recommend it for the very large, but it will be

comfortable for most. The seat is made of strapping and fabric, with the fabric

on the very bottom. Unlike the Comp buggy from PL, this buggy allows very easy

movement forward and back. There isn't any strapping to grab your bum.

The really nice feature of this buggy is the back tube. Although the pad they

supplied for the tube isn't very wide, that tube almost substitutes for a spring

back. A wider pad would enhance this even more. It's not perfect, as a spring

back gives you support from top to bottom and this tube is just a line across

your back. But for the buggier that wants to keep his center of gravity forward

most of the time, this tube can give his/hers stomach muscles an occasional

break.

When I was pulling it out of the box one of the first things I noticed was the

down tube. The adjustment holes weren't matched up perfectly across the width of

the square tube. They were off by about 3/16 of an inch (almost 0.5cm). So I

thought that, once assembled, the front end would lean to one side because the

side tubes would not be matched. So I test rode this buggy with my old front end

off my flexi buggy. Discussion with Ray at Cobra Kites revealed that because the

holes are bigger than the bolt, everything would line up. All the down tubes

have irregular drilled holes.

After one day at El Mirage I can say I like the buggy. The only concern I have

with it is when doing hard left turns, hard enough to slid the back wheels.

There was a creak/rattle sound coming from the left side. I checked the wheel

for a loose bolt. Nope. The only thing I can think is that the joint where the

back tube connects to the side tube is creaking. I'll look for a thin shim that

I can wrap around the tube before inserting it (maybe paper?).

Complaints.

The bolt that joins the side tubes across the down tube was welded on. Not a

major problem, just Dremel it off. But for the buggier that needs/likes to have

everything ready to go (which I'm not), this can be a real pain in the bum. With

it welded, in order to adjust the length, one needs to undo the seat and most of

the frame. With the bolt removable, one simply removes the bolt and slides the

down tube (if the down tube slides easily in-between the 'rails' of the side

tube, which mine didn't). Also, Ray indicated that some of the buggies have two

bolts there, and some down tubes have 6 holes (instead of the regular 5). So

some buggies have 3 adjustments, some have 5. Hmm..

The connectors on the seat need something to keep the strapping from sliding

through. On the strap that goes across the back of the seat, I had to tie the

tail to keep it tight. But there isn't that much tail available, so a simple

overhand knot had to suffice.

Ball bearing head set. I still just don't see the need. I've never heard of

anyone haven't problems with turning the front wheel. Jeez, you got your feet

over 20 inches apart, seems that would be plenty of leverage. I just don't get

it, another place to get salt water in and freeze up over time. It must be

cheaper to make them this way. The only advantage I see is that your buggy is

less likely to roll a great distance on the lake bed when your not in it.

Whoopee.

The bearing hole in the wheel seems a tad big. One of the wheels had a bearing

rolling around in the box when I got it. The bearing dropped into the wheel like

butter, no pressure needed. Now I worry (since I take my wheels off all the

time) if I'm going to lose a bearing.

Changes that I'll make to mine:

Stronger bolts. The bolts that are included aren't very hard, and the bumps at

Berkeley can loosen and bend bolts.

Cut off and replace the down tube/side tube bolt and nut. A locknut will keep it

from loosening.

Shim on the back tube where it goes into the side tubes. Get a longer pad for

the back tube.

Sew Velcro on the tails so that the seat straps don't loosen. Elongate one of

the front ones.

I'll be using my old front end on the new buggy, as it's down tube fits the

'rails' of the side tubes nicely. And the new front end fits my old side tubes

nicely. And the old front end doesn't have a BB headset.

Replace the buttons on the foot pegs with hard plastic end caps for 0.098 carbon

rods. These are then held in place from the outside with a small O ring. The

buttons that come with the buggy tend to stick and break over time (not to

mention that these seemed a little on the shallow side). Major bummer if you

don't have replacements (Dean found out that duct tape doesn't work to well).

Put large diameter bungee from foot peg to foot peg, to help keep feet on. I

drill a small hole in the end of the food peg and connect a small screw gate

carabiner from a hardware store (they are about 1.25" long). Then tie the

bungee to the biner and run it across the down tube. A 40" bungee cord from

a hardware store fits, with room for knots.

Gosh, with all these changes seems that I wouldn't like the buggy. But I like to

fiddle. I haven't decided as to weather I'll replace the seat with one that puts

me further forward (like I did on my old one).

Disclaimer: This review is for entertainment purposes only. No connection to the

manufacturer or it's distributors should be inferred (there isn't). I'm

5'8" tall, 152 lbs. Your price and mileage may vary.